How do DTF printers overcome the shortcomings of traditional printers?

In the printing industry, although traditional printing technologies (such as screen printing, thermal transfer and DTG direct injection) are widely used, they still have many limitations, such as high cost, low efficiency, and insufficient color performance. The emergence of DTF (Direct to Film) printingtechnology has brought revolutionary changes to the industry. As a professional digital printing service provider, Enprinting helps users break through the bottleneck of traditional printing. This article will compare the shortcomings of traditional printing technologies and analyze how DTF Printers can provide better solutions.

Limitations of traditional printing technology

- Screen printing: low efficiency and high cost for small batches

Screen printing is suitable for mass production, but the plate making time is long, and each time a color is changed, the plate needs to be re-made, resulting in extremely high costs for small batch orders. In addition, complex multi-color patterns are difficult to print and cannot meet personalized customization needs.

- Thermal transfer: hard feel and poor breathability

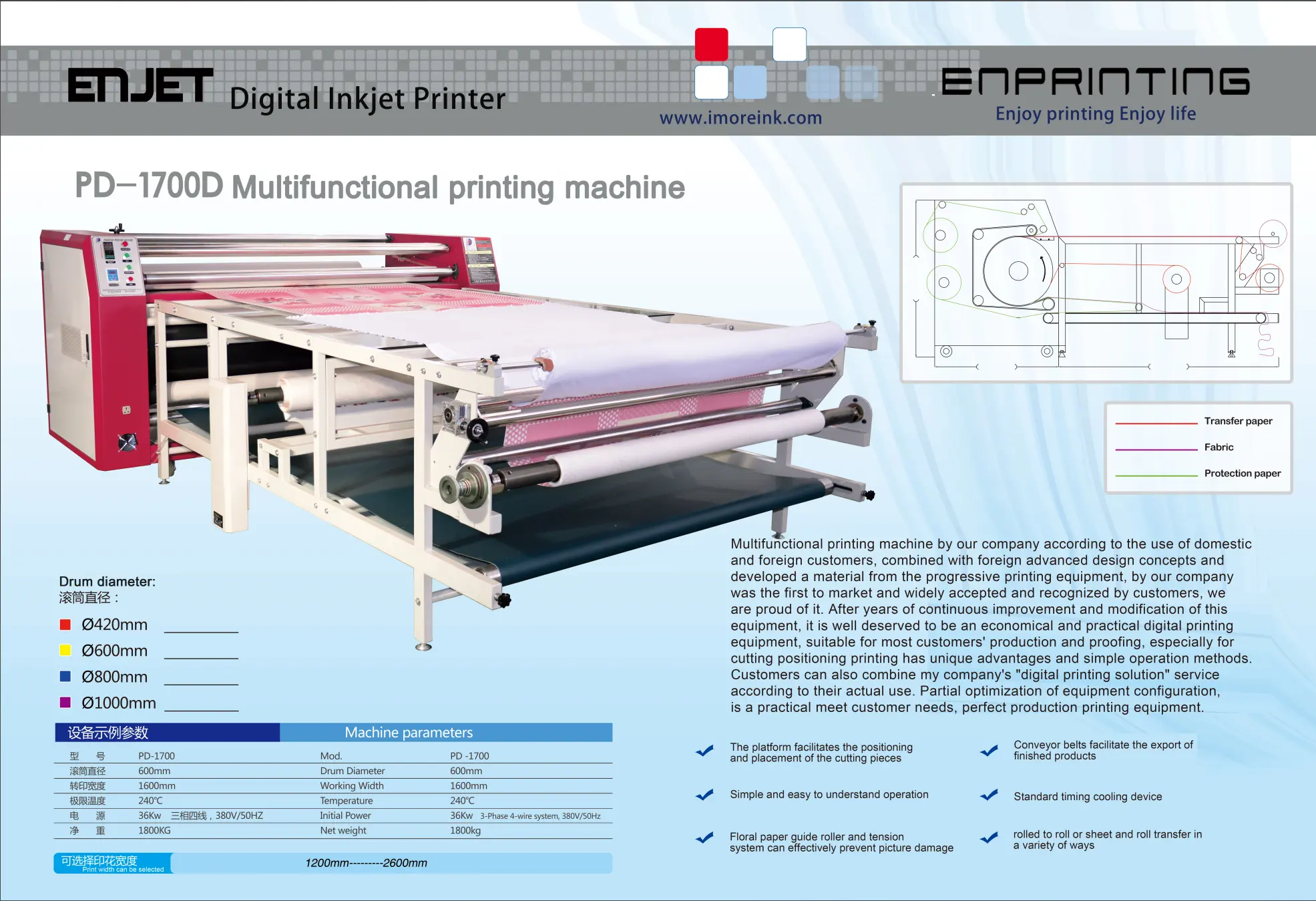

Thermal transfer transfers the pattern to clothing through high temperature, but the finished product often feels stiff, affecting wearing comfort. At the same time, dark fabrics require additional white base ink, which increases the process and cost.

- DTG direct printing: high requirements for fabrics and high maintenance costs

Although DTG (Direct To Garment) printers can achieve high-precision printing, they are only suitable for pure cotton or high-cotton fabrics, and require pre-treatment liquid, slow printing speed, easy clogging of the nozzle, and high maintenance costs.

Advantages of DTF printers

- Wide applicability, not limited by fabrics

Enprinting DTF printers can print on a variety of materials such as cotton, polyester, nylon, denim, and even leather. No pre-treatment is required, and the transfer is completed directly through the thermal transfer film, which greatly expands the application scenarios.

- Bright colors and excellent details

Traditional printing technologies (such as screen printing) perform poorly on gradient colors and complex patterns, while DTF uses high-precision inkjet technology to present richer color levels and delicate details, comparable to digital printing effects.

- Small batch production is more economical

Compared to screen printing, which requires plate making, DTF does not require plate making and can be printed in single pieces. It is particularly suitable for personalized customization, sample proofing and small batch orders, reducing production costs.

- Soft feel and high durability

The pattern printed by DTF is bonded by hot melt adhesive film, which is not only soft and breathable, but also washable and wear-resistant. It is not easy to crack and fall off after long-term use, which is better than the rigid feel of traditional thermal transfer.

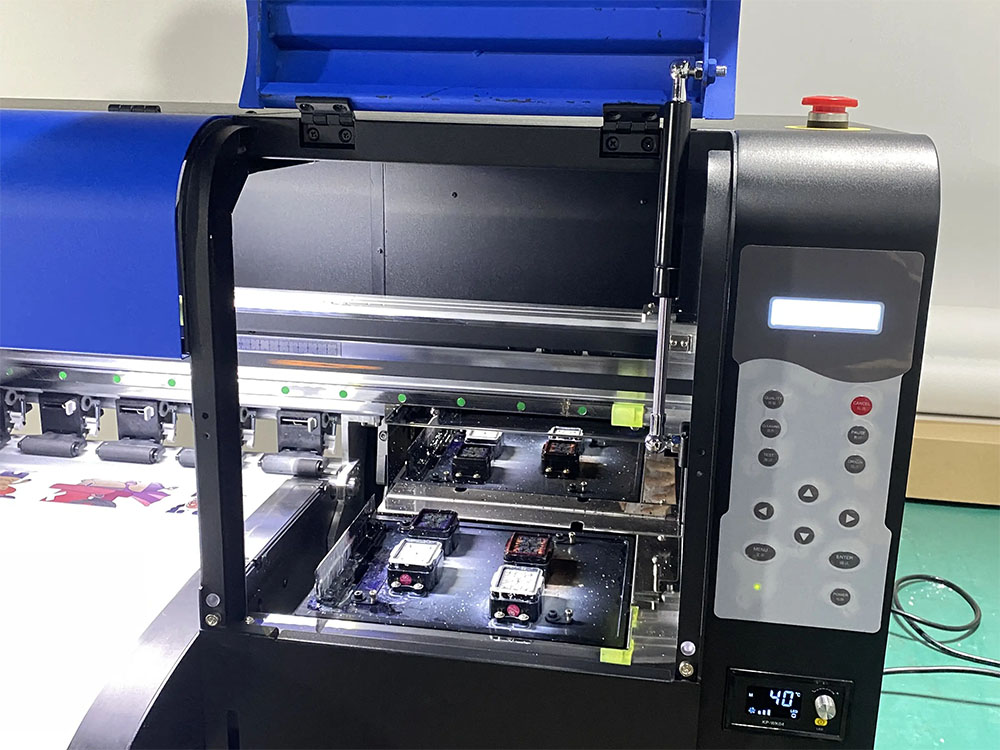

- Simple operation and convenient maintenance

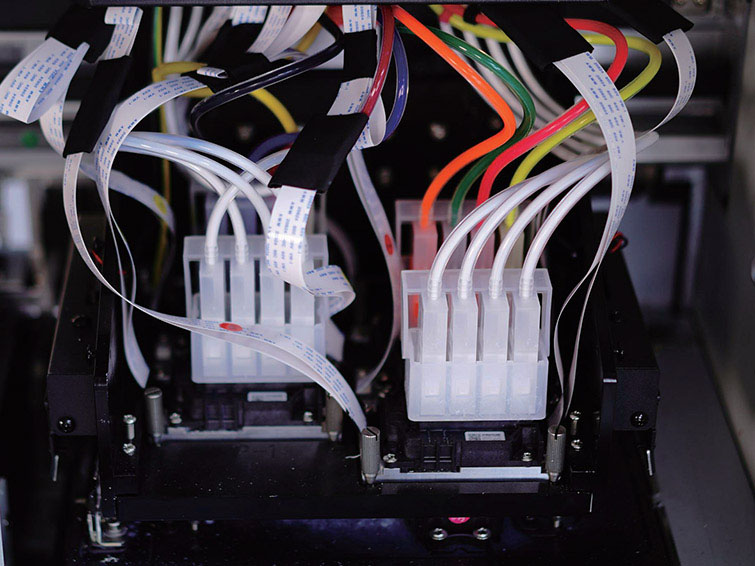

Enprinting DTF printer adopts intelligent ink supply system and automatic cleaning function to reduce the risk of nozzle clogging and maintenance cost. Even non-professionals can quickly get started.

Why choose Enprinting DTF printer?

As a professional digital printing solution service provider, Enprinting provides high-performance and high-stability DTF printing solutions with the following core advantages:

High-precision printing: using industrial-grade nozzles to ensure clear and sharp patterns.

Efficient production: supports batch continuous printing to improve production capacity.

Intelligent system: equipped with automatic ink supply and nozzle protection functions to reduce manual intervention.

Environmental protection and energy saving: low energy consumption design, in line with the trend of modern green production.

Conclusion

Traditional printing technology is limited by efficiency, cost and applicability, and it is difficult to meet the needs of the modern printing market. However, DTF printing technology is becoming a new trend in the industry with its wide material adaptability, excellent color performance and economical small batch production capacity. As a professional digital printing service provider, Enprinting is committed to providing customers with efficient, stable and cost-effective printing solutions to help companies improve their competitiveness and seize market opportunities.

If you want to upgrade your printing process and improve production efficiency, you might as well try Enprinting DTF printer to experience the changes brought about by the new generation of printing technology!