How to choose a digital printing solution that suits your business?

As the textile industry continues to transform towards flexible production, small batch customization and fast delivery, digital printing technology is becoming the first choice for more and more companies. But faced with a wide variety of equipment and technical routes on the market, how can you choose a digital printing solution that is truly suitable for your business? This is not only related to the return on investment of equipment, but also affects production efficiency, product quality and market competitiveness.

This article will help you sort out your selection ideas from multiple key dimensions and find the solution that best suits your business needs.

Clarify your business positioning and production needs

Before choosing a digital printing solution, you must first clarify your own business model:

Are you doing clothing customization, home textile products, or industrial fabrics?

Are the products mainly small batches and multiple styles, or do you have higher production requirements?

How high are the requirements for printing accuracy and color reproduction?

Are there special demands such as environmental protection, flexibility or fast delivery?

For example, e-commerce customization customers are usually more concerned with flexibility and diversity, while large factories are more concerned with production capacity and cost control.

Choose the right printing method: direct printing vs. thermal sublimation vs. heat transfer

1. Thermal sublimation printing

Suitable for chemical fiber fabrics such as polyester, often used in sportswear, advertising flags and other fields. Features include bright colors, strong adhesion, and stable batch production capacity.

2. Direct coating printing

Suitable for natural fiber fabrics such as pure cotton and linen. No need for steaming and washing, environmentally friendly and simple, suitable for quick-return products such as T-shirts and canvas bags.

3. White ink heat transfer (DTF)

Supports a variety of materials, including polyester, blended, leather, etc., suitable for small batch, high-precision, multi-variety customization, and widely used in clothing, bags, shoes and hats and other industries.

Different solutions perform differently in terms of proofing speed, color fastness, softness, etc. You can choose the most matching printing path according to the actual application scenario.

Evaluate production capacity and automation level

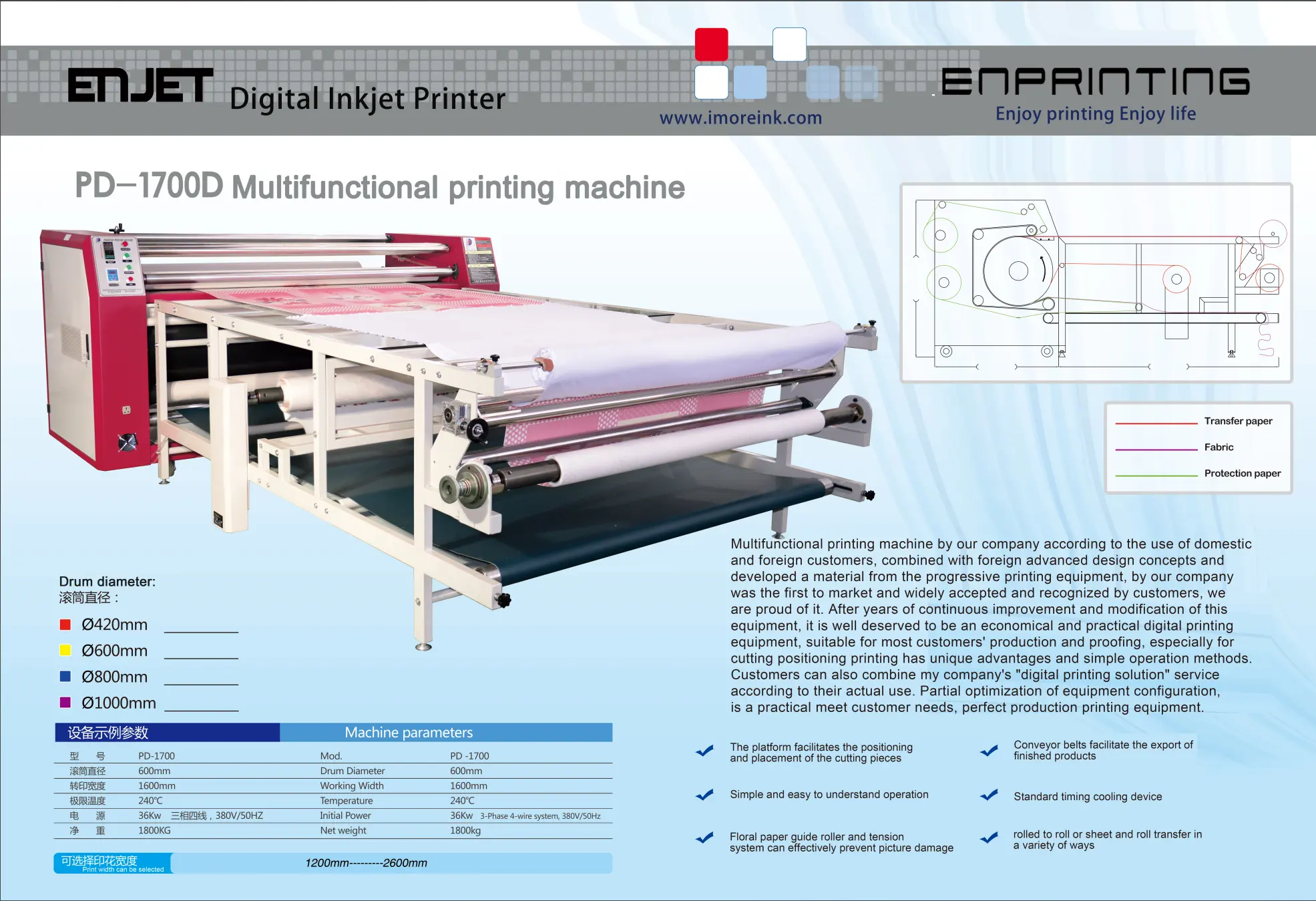

The number of nozzles, printing width and paper feed speed of different machines directly affect production capacity.

If you have a large number of orders every day, it is recommended to choose a multi-nozzle industrial printer (such as the Enjet 36-head series) that supports high-speed and high-precision printing.

If you mainly do small batches, you can choose a small or medium-sized thermal Sublimation Machine or heat transfer machine with a high cost-effectiveness, which saves space and is convenient for proofing.

In addition, whether it is equipped with an automatic paper collection system, automatic temperature control, remote monitoring and other functions is also the key to improving efficiency and reducing labor costs.

Pay attention to consumables and long-term operating costs

Different printing solutions require different types of consumables (such as ink, transfer paper, film, etc.), and the long-term consumption cost is also an important consideration.

High-quality nozzle ink can greatly improve printing stability and pattern restoration;

Reasonable consumable configuration and ink supply system can reduce scrap rate;

Is the supply chain stable? Does it support customized color matching?

It is recommended to cooperate with manufacturers with a complete consumable supply and after-sales system to reduce the risk of long-term use.

Manufacturer service capabilities and technical support

Choosing a digital printing solution is not only about buying a device, but also about establishing a complete production system. At this time, a partner with rich industry experience and perfect after-sales service is particularly important.

Like us, Enprinting has more than ten years of industry experience, and the engineering team covers the whole country. We can provide customers with one-stop services including proofing testing, solution customization, remote training, and on-site debugging to ensure stable operation of the machine and help customers quickly put into production.

If you want to know more about digital printing solutions, please contact us!