What is a high-speed digital belt direct-injection machine for textile fabrics?

Unlocking the core technology of modern textile printing

In the textile printing industry, efficient and high-precision printing technology is constantly promoting the transformation of production models. Among them, the "high-speed textile fabric digital guide belt direct injection machine" as a core equipment that has attracted much attention in recent years is becoming a new main force in the field of digital printing. So, what is this machine? What are its advantages? What scenarios is it suitable for? Today we will analyze it comprehensively.

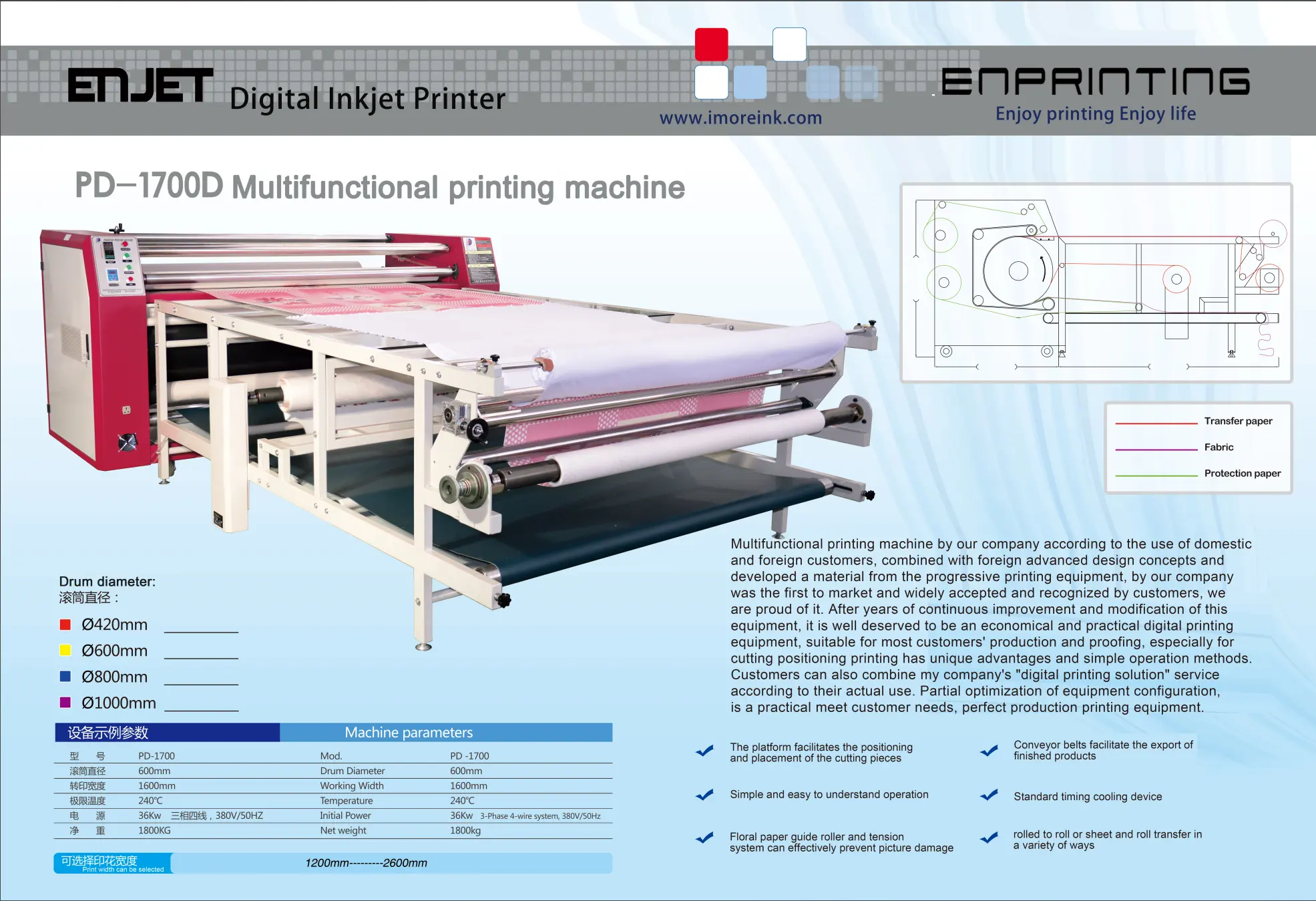

1. What is a high-speed textile fabric digital guide belt direct injection machine?

High-speed textile fabric digital guide belt direct injection machine is a digital printing device designed for direct printing of patterns on textile fabrics. Unlike traditional thermal transfer and screen printing, this type of equipment uses Inkjet technology to spray dye or pigment ink directly onto the fabric through the nozzle, and uses the guide belt system to achieve precise delivery and positioning, thereby completing high-speed and high-precision large-format pattern printing.

Keyword explanation:

High speed: supports printing capacity of hundreds to thousands of square meters per hour;

Digital direct printing: no plate making is required, the pattern is directly controlled by the computer to spray out the nozzle;

Belt guide system: conveys the fabric and keeps it flat and consistent with tension, which is the key structure to ensure high-precision printing.

2. Advantages of high-speed belt guide direct Printing Machine

High efficiency

With the help of high-speed nozzles and precision belt guide system, one device can complete large-scale printing tasks in a short time, which is very suitable for industrial production.

Unlimited pattern

Supports any pattern, gradient, photo-level details, and can also realize on-demand printing without color quantity restrictions.

Adapt to a variety of fabrics

Can be used for different materials such as pure cotton, silk, polyester, linen, blended, etc., just change the corresponding ink type.

Green and environmentally friendly

Compared with traditional processes, it reduces a lot of water use and chemical emissions, which is more in line with the trend of sustainable development.

3. Applicable scenarios and development prospects

High-speed digital belt direct-injection machine is particularly suitable for:

Printing of mid-to-high-end clothing fabrics

Home textiles (such as curtains, bedding, and sofa fabrics)

Personalized customization (such as cultural shirts, customized clothing)

Quick proofing and small batch orders

With the increase in consumer demand for "fast, personalized, and environmentally friendly" products, belt direct-injection machines will play an increasingly important role in flexible manufacturing and rapid response supply chains.

4. Conclusion

High-speed digital belt direct-injection machine for textile fabrics is not only an innovation in equipment technology, but also a microcosm of the digital transformation of the textile printing industry. It breaks the limitations of traditional printing and provides designers and manufacturers with a broader creative space and production freedom. If you are considering upgrading your production line and expanding your diversified products, you might as well learn more about this technology. Perhaps it will be your next trump card.